Casting

Casting is called the mother of industry, and it is also a processing technology that has been passed down for thousands of years in China. Uimco has a history of nearly 40 years in casting, starting from the most primitive hand-made sand-casting mold and progressing to molding machines. While the scale of the company expanded, the market demand increased and Uimco responded through utilizing innovative technology. We currently utilize a modern and fully automatic molding production line. We not only provide more stable casting quality, and expanding production capacity, but also successfully meet the need for rising environmental awareness. With years of accumulated casting experience, our corresponding production parameters are formulated for products of various sizes and shapes. We pride ourselves in meeting the standards required by customers, including the strength, size, and appearance of castings.

Grinding

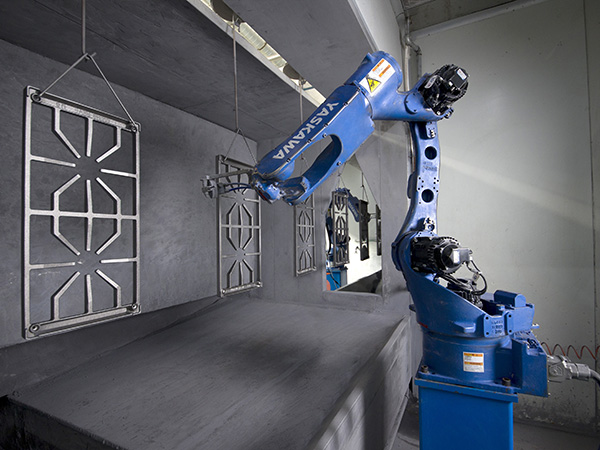

Grinding is the most labor-intensive and time-consuming part of casting products. Over the past 40 years, Uimco has produced large and small products with many different shapes and features. Our skilled technicians utilize rough grinding and fine grinding. Additionally, in response to the shortage of grinders and the aging of manpower, Uimco introduced the robotic arm in 2020 for our automatic grinding equipment. This robotic arm will greatly reduce the need for grinding manpower, and it provides more stable quality and higher production efficiency. Presently, nearly 80% of products utilize the robotic arm technology.

Grinding

Grinding is the most labor-intensive and time-consuming part of casting products. Over the past 40 years, Uimco has produced large and small products with many different shapes and features. Our skilled technicians utilize rough grinding and fine grinding. Additionally, in response to the shortage of grinders and the aging of manpower, Uimco introduced the robotic arm in 2020 for our automatic grinding equipment. This robotic arm will greatly reduce the need for grinding manpower, and it provides more stable quality and higher production efficiency. Presently, nearly 80% of products utilize the robotic arm technology.

Porcelain coating

Porcelain (enamel) is a kind of glass material. After being liquefied at a high temperature of about 650°C to 760°C, it is sprayed on the surface of cast iron, and formed into a coating through sintering, cooling, and other processes. Due to the characteristics of high temperature resistance, non-toxicity, easy cleaning, and beautiful appearance, it is widely used in kitchen parts, such as grates and pots. Uimco has electrostatic disc spraying equipment, robotic arm for automatic spraying, and other diversified spraying equipment. We match the various spraying methods according to the specific shapes of the products, so that we can ensure the stable quality of the porcelain coating, and meet the maximum economic benefit of mass production, while providing customers with high-quality and competitive prices.

CNC

Uimco has several CNC horizontal/vertical processing machines. The molds required for casting and the fixtures required for grinding are produced and maintained by Uimco itself. In response to customer urgent needs, we can quickly make additional molds to increase production capacity. In addition to mold making, CNC machines are also used in the machining required for food processing machine parts, such as grooving, drilling, and turning. We will also inspect the product with our coordinate measuring machine to ensure dimensional accuracy.

CNC

Uimco has several CNC horizontal/vertical processing machines. The molds required for casting and the fixtures required for grinding are produced and maintained by Uimco itself. In response to customer urgent needs, we can quickly make additional molds to increase production capacity. In addition to mold making, CNC machines are also used in the machining required for food processing machine parts, such as grooving, drilling, and turning. We will also inspect the product with our coordinate measuring machine to ensure dimensional accuracy.